The Los Angeles Abrasion Test is a common method used to assess the abrasion resistance of aggregates. In India, the relevant standard for this test is IS 2386 (Part IV): 1963, “Methods of Test for Aggregates for Concrete: Mechanical Properties.”

Here is a basic outline of the methodology for the Los Angeles Abrasion Test as per the Indian standard:

Equipment Required:

- Los Angeles abrasion testing machine

- Abrasive charge: steel balls (approximately 46 mm in diameter and weighing between 390 and 445 grams)

- Abrasive charge tray

- Sieve: 1.7 mm opening

- Balance: accurate to 1 gram

- Drying oven

- Round pan or container

- Tamping rod

Procedure Los Angeles Abrasion Test :

1. Sample Preparation:

- Obtain a representative sample of the aggregate to be tested.

- Wash the sample and oven-dry it to a constant weight at a temperature not exceeding 110°C.

2. Los Angeles Abrasion Test:

- Weigh the dry sample to the nearest gram and place it in the Los Angeles abrasion testing machine.

- Start the machine and allow it to run for a specified number of revolutions (usually 500).

- At the end of the test, stop the machine and discharge the material into a pan.

- Dry the material retained on the 1.7 mm sieve in an oven and weigh it to the nearest gram.

Calculation:

- Calculate the Los Angeles abrasion value as the percentage of the original weight of the test sample retained on the 1.7 mm sieve after the specified number of revolutions.

Los Angeles Abrasion Value (%) = (Weight of the oven-dried sample retained on the 1.7 mm sieve / Initial weight of the dry sample) * 100

Reporting:

Report the Los Angeles Abrasion Value as the average of three tests on the same material.

Notes:

- The test may be repeated if the results are inconsistent.

- The test should be performed in a dry condition.

Always refer to the latest version of the Indian Standard IS 2386 (Part IV): 1963 for the most accurate and up-to-date procedure, as standards may be revised over time.

Example Los Angeles Abrasion Test :

Given Data:

- Initial weight of dry sample = 2000 grams

- Number of revolutions = 500

- Weight of oven-dried sample retained on the 1.7 mm sieve after the test = 1500 grams

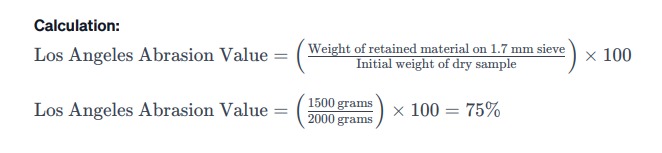

Calculation:

Conclusion:

The Los Angeles Abrasion Value for the tested aggregate is 75%. This means that, after 500 revolutions in the Los Angeles abrasion testing machine, 75% of the original sample weight was retained on the 1.7 mm sieve. A lower value indicates better abrasion resistance. Always compare your result with any relevant specifications or standards for acceptance criteria.