The California Bearing Ratio (CBR) test is a common method used to evaluate the mechanical strength of subgrade soils and base course materials for pavement design. In India, the Indian Standard (IS) code that provides guidelines for the CBR test is IS 2720 Part 16: “Methods of Test for Soils – Laboratory Determination of CBR.”

Here is a general methodology for conducting the CBR test according to the Indian Standard:

Equipment and Apparatus:

- CBR Testing Machine: The machine should comply with the requirements of IS 2720 Part 16.

- Molds: Cylindrical molds with an internal diameter of 150 mm and a height of 175 mm.

- Penetration Piston: A penetration piston with a diameter of 50 mm and a face area of 20 cm².

- Spacer Discs: Two spacer discs to fit within the mold and piston.

- Annular Metal Surcharge Weight: A metal surcharge weight with an annular seating ring.

- Proving Ring and Dial Gauge: A proving ring and a dial gauge for measuring the penetration.

CBR Test Procedure:

- Sample Preparation: The soil sample should be prepared to the required moisture content and placed in the mold in three or more layers. Each layer should be compacted to the specified number of blows using a rammer.

- Soak the Sample: Soak the compacted sample for four days in water.

- Assemble the Apparatus: Assemble the CBR apparatus with the mold containing the soaked sample, penetration piston, spacer discs, and surcharge weight.

- Apply the Initial Load: Apply an initial load to the sample using the penetration piston. This load should be sufficient to seat the piston on the sample.

- Record Initial Readings: Record the initial dial gauge reading and apply the required surcharge load.

- Perform Penetration Test: Start the penetration test at a constant rate of penetration and record the load and corresponding penetration values at regular intervals.

- Continue the Test: Continue the test until the penetration reaches a specified value (usually 2.5 mm).

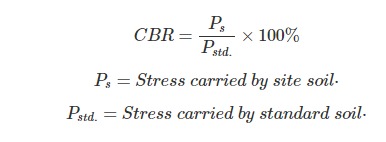

- Calculate CBR Value: Calculate the CBR value using the formula:

- [CBR = \frac{{\text{Test Load (kN)}}}{{\text{Standard Load for Crushed Stone (kN)}}} \times 100]

formula for calculation in california bearing ratio apparatus

Reporting:

- Report Format: Prepare a test report including details of the soil sample, moisture content, compaction method, and the results of the CBR test.

- CBR Values: Report the CBR values at the specified penetration (e.g., 2.5 mm) and any other relevant information.

Types / sizes of california bearing ratio apparatus

The California Bearing Ratio (CBR) apparatus includes a cylindrical mold with a 150 mm diameter and 175 mm height. The mold also has a 50 mm collar and a detachable perforated base. Other components of the apparatus include:

- A 2.5 kg compaction rammer and surcharge annular with a 147 mm diameter

- A 50 mm penetration piston with an adjustable bracket for a dial gauge

- A 148 mm diameter circular metal spacer disc with a detachable handle

The CBR apparatus also includes:

- Test sieves with aperture sizes of 20 mm and 5 mm

- A hand-operated load frame with a capacity of 5000 kg (50 KN)

- A cutting collar

- A perforated swell plate

- A metallic ring made of mild steel

- A metal tripod made of aluminum

- A penetration piston assembly

When buying a CBR apparatus, you can consider things like:

- Compatibility with different soil types

- Brand reputation and customer support

- Accuracy and reliability

- Ease of use and maintenance

The CBR is a measure of the strength of the subgrade of a road or other paved area, and of the materials used in its construction. The ratio is measured using a standardized penetration test.

Example CBR Test:

Sample Information:

- Type of Soil: Sandy Clay

- Moisture Content: 10%

- Compaction Method: Standard Proctor Compaction

- Penetration: 2.5 mm

Apparatus:

- CBR Testing Machine

- Mold (150 mm diameter, 175 mm height)

- Penetration Piston (50 mm diameter)

- Spacer Discs

- Surcharge Weight

- Proving Ring

- Dial Gauge

Test Procedure:

- Sample Preparation: A soil sample is prepared to a moisture content of 10% and compacted in the mold in three layers using a standard Proctor compaction method.

- Soak the Sample: The compacted sample is soaked in water for four days.

- Assemble the Apparatus: The CBR apparatus is assembled with the mold containing the soaked sample, penetration piston, spacer discs, and surcharge weight.

- Apply Initial Load: An initial load is applied to the sample using the penetration piston to seat it.

- Record Initial Readings: The initial dial gauge reading is recorded, and the required surcharge load is applied.

- Perform Penetration Test: The penetration test is started at a constant rate, and load and penetration values are recorded at regular intervals.

- Continue the Test: The test continues until the penetration reaches 2.5 mm.

- Calculate CBR Value: The CBR value is calculated using the formula:

- [CBR = \frac{{\text{Test Load (kN)}}}{{\text{Standard Load for Crushed Stone (kN)}}} \times 100]

Reporting:

- Test Results: The CBR value at 2.5 mm penetration is calculated (e.g., CBR = 80%).

- Test Report: A comprehensive test report is prepared, including details of the soil sample, moisture content, compaction method, and the CBR results.

Remember that this is a simplified example, and actual testing involves more meticulous procedures, precise measurements, and adherence to the specific requirements outlined in the Indian Standard IS 2720 Part 16. Always refer to the latest version of the standard for accurate and detailed information.