METHODOLOGY FOR WET MIX MACADAM

(Acceptance criteria: Ref: Sec. 406 of MORT&H)

This item of work deals with construction of wet mix macadam with approved materials as per the specifications of contract agreement.

General

This item of work shall be dealt in compliance to the clause 406 of specifications.

The construction shall confirm to the specific alignment, lines and grades given in the drawing.

Procedure

Preparation of Mix:

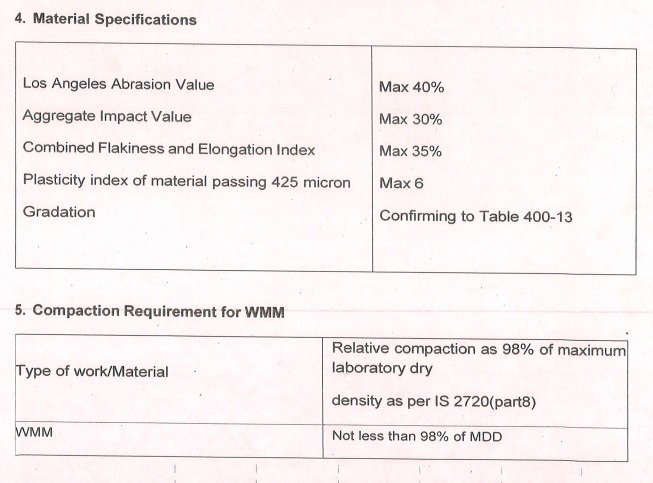

- The individual materials gradation shall be checked combined, proportions shall be fixed and combined gradation confirming to table 400-13 shall be arrived.

- The individual bins of wet mix plant shall be calibrated for the particular size of material.

- Material shall be fed to the mixing plant bins provided for individual sizes of aggregates to meet the required gradation.

- Mixing plant shall be of suitable capacity having provision for controlled addition of water.

- While adding water, loss due to evaporation shall be taken in account.

Preparation of Base:

- The sub base shall be checked for proper lines and levels.

- It shall be made free from dust. Before the laying starts it should be made slightly wet and shall be given one plain pass.

- The lateral confinement for wet mix shall be provided by placing material in the adjoining shoulder portion.

Laying of Wet Mix Macadam (WMM):

- The wet mix shall be transported from the mixing plant to the site with trippers The mix shall be laid with suitable Paver or Motor grader.

- The mix shall be laid manually in places where the paver movement is not possible.

- High or low spots shall be rectified by adding or removal of materials as the case may be.

- The material shall be uniform and shall be free of pockets of fine material.

- As per clause 406.3.5. Of MORT&H, maximum single compacted layer should not be more than 200mm. But designed thickness is 250 mm hence it will be done in 2 layers equally. The rolling shall be done with 80-100KN vibratory roller. The rolling pattern shall be established in the trial stretch.

- Care shall be given at every stage so that there will not be any segregation.

- The finished layer shall be checked for compaction in accordance to the specifications given below. The top shall be checked for level control and shall be within +10mm and -10mm of designed level.

- All relevant QA & QC documents will be maintained for all stages of construction.

Equipment/Machinery OF WMM

WMM Plant-1 No

Sensor Paver / Grader -1 No

Tippers : 5 Nos as a minimum

Roller (Vibratory) 80 to 100kN -1 No as a minimum