METHODOLOGY FOR CONSTRUCTION OF GRANULAR SUB BASE

(Non-Bituminous)

(Acceptance criteria: Ref. Sec. 400 of MORT&H)

Scope:

This work shall consist of laying and compacting well-graded material on prepared subgrade for widening/ new construction of carriageway, hard shoulders, service roads, etc.

Equipment Requirement OF GSB :

- Crusher

- Wheel loader

- Tipper

- Grader

- Water tanker

- Roller

Material OF GSB :

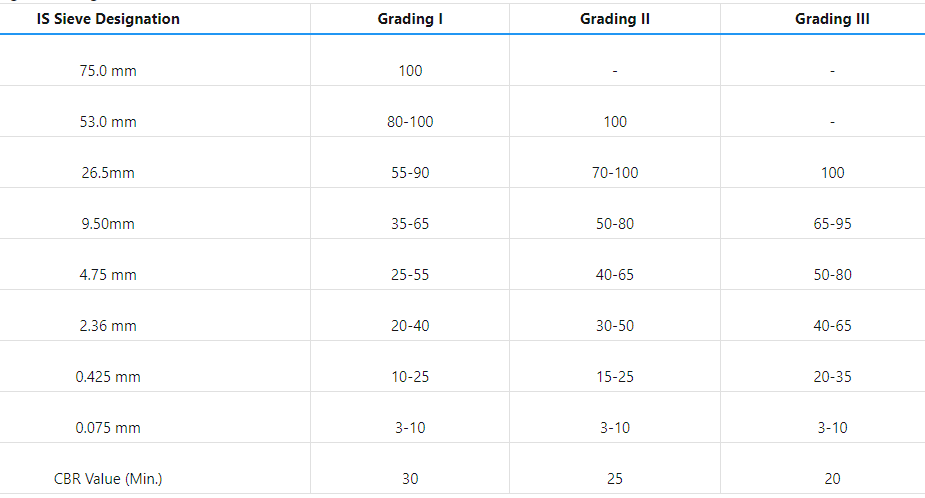

The material to be used for the work shall be crushed stone only. The material shall be free From Organic or other deleterious constituents and confirm to the Grading I given in Table

“The material to be used shall have AIV value not more than 40%. LL not more than 25 &PI value not more than 6% and if water absorption is more than 2%, soundness test shall be carried out.”

Procedure for construction OF GSB :

- The sub-base material shall be spread into 2 layers and each layer should be 125mm Compacted thickness on the Approved subgrade with the help of mechanical means to the required slopes and grades.

- The moisture content shall be checked and if required any shall be add by sprinkling, within the range of 1% to 2% below OMC.

- The material shall be then compacted with vibratory rollers.

- The compacted thickness of layer shall not exceed 200mm.

- The rolling shall commence form lower edge and proceed towards the upper edge. Each pass of the roller shall overlap 1/3 rd of the preceding. During rolling the grades, cambers are to be checked and any depressions or high spots are to be rectified by adding or removing the material.

- The rolling shall be continued till achieving the compaction of 98% of MDD.

- Field dry density will be carried out by sand replacement method and recorded.

- During the period of construction arrangement of traffic shall be in accordance with MORT&H 112.